Our Comprehensive Services

At Urethane Casting Services, we provide tailored solutions for rapid prototyping and low-volume manufacturing. Discover high-quality, efficient, and cost-effective options for your business needs.

Urethane Casting Services

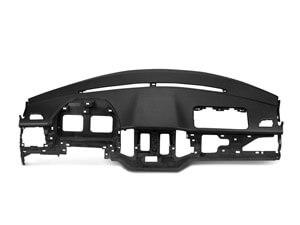

Our urethane casting service utilizes advanced silicone molds to create high-quality plastic parts. This method is perfect for both prototyping and small-batch production, minimizing lead times. Clients benefit from a quick turnaround and reduced costs compared to traditional manufacturing methods. Experience the flexibility and precision that urethane casting can offer for your projects.

What is Urethane Casting?

Urethane Casting is a highly efficient low-volume manufacturing process that utilizes silicone molds to produce high-quality plastic parts. This process is ideal for prototyping and small-batch production, offering a cost-effective and time-saving alternative to traditional injection molding.

By using a master model (typically created through CNC machining or 3D printing), we produce silicone molds that allow us to cast multiple identical parts. These parts can closely replicate the properties and appearance of injection-molded components, making Urethane Casting a preferred choice for product development and market testing.

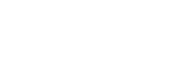

Main Urethane Casting Process

Master Model Creation – A high-precision master model is produced using CNC machining or 3D printing.

Silicone Mold Making – The master model is placed in a liquid silicone mold, which cures and forms a negative cavity.

Vacuum Casting – Liquid polyurethane resin is poured into the silicone mold under vacuum conditions to eliminate air bubbles and ensure consistency.

Curing & Demolding – The cast part is cured, removed from the mold, and undergoes necessary post-processing.

Urethane Casting Materials

Polyurethane is a widely used thermoset material grouping known for its strength, durability, abrasion resistance, and versatility. Different urethanes can mimic the properties of many common thermoplastics.

For example, a stiff urethane cast part is “polycarbonate-like,” and a more flexible plastic may be “polypropylene-like”. We group our urethane materials into general categories to help you make quicker decisions and get the best performance on your project.

The list below describes the categories of materials and technical examples when selecting polyurethanes.

Cast Urethane Materials

| Material Name | Shore Hardness | Description | Technical Information | Data Sheets |

|---|---|---|---|---|

| General Purpose | Shore D 76-80 | An impact-resistant Shore 78D material used for a variety of purposes, from enclosure housings to concept models. This material exhibits ABS-like properties. | TC-878, TC-852, or equivalent | General Purpose Data Sheet |

| Rigid Clear | Shore D 80 | A versatile, Shore D 80, clear polyurethane. A matte finish will give a frosted appearance and a higher gloss will increase its transparency. | Poly-Optic 1410 or equivalent | Rigid Clear Data Sheet |

| ABS-Like, FR | Shore D 78-82 | A tough Shore 80D flame retardant material that is UL Listed with a flammability rating at 1/16″ (1.6 mm). | TC-891-FR or equivalent | ABS-Like, FR Data Sheet |

| Polypropylene-Like | Shore D 65-75 | A tough and abrasion-resistant flexible urethane with polypropylene-like ductility. | TC-872, HP-2270D, or equivalent | Polypropylene-Like Data Sheet |

| Polycarbonate-Like | Shore D 82-86 | A stiff, high impact, high HDT, material with a wide variety of uses. Simulates polycarbonate (non-clear), Shore 84D. | TC-854 or equivalent | Polycarbonate-Like Data Sheet |

| Glass-Filled Nylon-Like | Shore D 85 | A stiff, USP Class VI, high-performance urethane with high impact strength and a HDT of 190°F (88°C). | PT8902 or PT8952 (FR) | Glass-Filled Nylon-Like Data Sheet |

| Rubber-Like Polyurethane | Shore A 25-95 | A Shore A elastomer with a high elongation to break. | F-130 to F-190 or equivalent | Rubber-Like Polyurethane Data Sheet |

| Clear Rubber-Like Polyurethane | Shore A 40-95 | A colorless Shore A elastomer with a high elongation to break. Matte finish will give a frosted appearance, and higher gloss will increase its transparency. | WC-540 to WC-595 or equivalent | Clear Rubber-Like Polyurethane Data Sheet |

Cast Silicone Materials

Silicone is not only used for making tools in casting, but it is also an excellent material for parts. Silicone is durable, stretchy, tear-resistant, inert, easy to clean, and has a high-temperature resistance. Silicone rubber can achieve ultra-soft durometers as low as Shore A 10 and up to medium-hard rubbers in the Shore A 60 range. Silicone casting is ideal for medical devices, surgical models, props, soft-touch housings, kitchen accessories, and more.

- Shore A 10 (TC-5005 or equiv.)

- Shore A 20-30 (TC-5130 or equiv.)

- Shore A 30-40 (TC-5140 or equiv.)

- Shore A 40-50 (TC-5150 or equiv.)

- Shore A 50-60 (Smooth‑Sil™ 960 or equiv.)

Surface Finishing & Post-Processing

To enhance both the aesthetics and functionality of your parts, we provide:

- Basic Finishing – Deburring, sanding, and polishing.

- Painting & Coating – Custom colors, glossy/matte finishes, and protective coatings.

- Texture & Printing – Silk-screening, pad printing, and laser engraving.

- Metallic Effects – Chrome plating, anodizing, and vacuum metallization.